Calculus Industries (Pty) Ltd. (“Calculus” or the “Company”) is pleased to provide highlights from the Definitive Feasibility Study for the Company’s Chloralkali Plant Project located in Arandis, Erongo.

Highlights include:

- Average annual production of 14,147 tonnes of calcium chloride, 14,388 tonnes of caustic soda flakes, 6,600 tonnes of caustic lye, 5,610 tonnes of liquid carbon dioxide, 5,000 tonnes of liquid chlorine, and 1,000 tonnes of hydrochloric acid per annum. The plant will also have the swing capacity to produce 49,500 tonnes of 15% sodium hypochlorite.

- EBIDTA of N$ 148,634,617.

- NPVof N$ 193,492,228 with an IRR of 22%.

- Capital expenditure of N$ 882,841,064.

- Total project net cash flows of N$ 901,858,981.

Calculus is a private limited company, incorporated in the Republic of Namibia. The company is setting up a greenfield chloralkali plant in Arandis. Construction of the plant is expected to start in the last quarter of 2020 and will take approximately 24-months. Commissioning is planned for the fourth quarter of 2022.

An environmental impact assessment was conducted in 2019, and an environmental clearance certificate was awarded by the Ministry of Environment and Tourism at the beginning of this year. The plant will be located at the Calculus Chemical Complex, which is an envisioned site currently being established in Arandis. The total site area is 15,000 square metres and is 90 kilometres away from the port of Walvis Bay. The plant will be constructed by an internationally well reputed engineering firm under an Engineering, Procurement and Construction contract.

During the construction period, it is estimated that over 400 people will be employed at the site, for two years, while 140 permanent jobs will be created once the plant is in operation. The total direct, indirect and induced impact is estimated at N$ 250 million per year. Much of this amount will be captured in the Erongo regional economy.

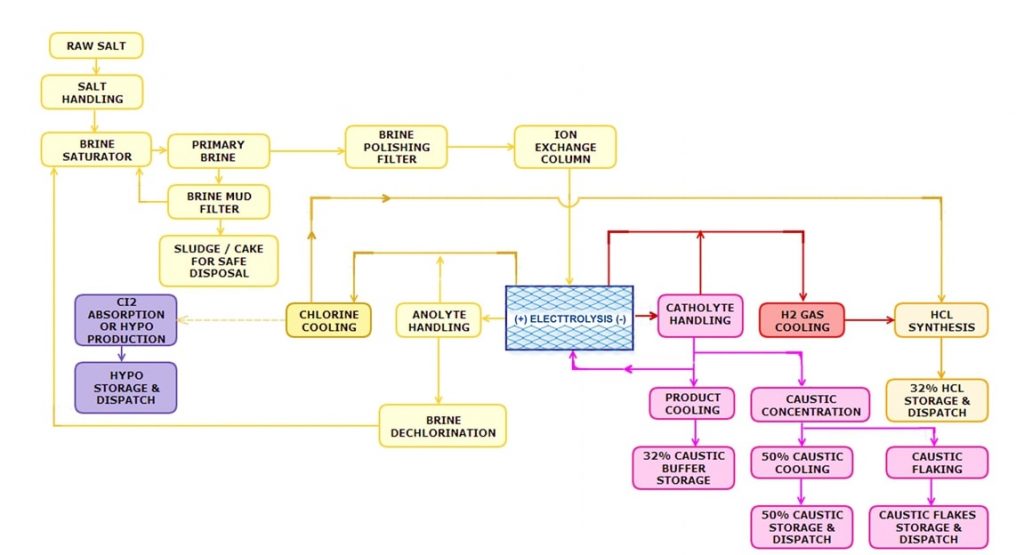

Salt is the primary raw material for the chloralkali process. Chemical grade salt (99%) is required as an input into the process at 26,400 tonnes per annum. The salt will be purchased from a solar salt mine at Cape Cross and transported to site via road (180 km). The salt will be off-loaded from the road trucks onto a salt storage patio with the capacity to store 2,000 tonnes of salt.

Calcium carbonate will be used to produce calcium chloride and carbon dioxide. Industrial grade calcium carbonate (96%) will be sourced from the SwaCa quarry mine outside Swakopmund. A total of 13,000 tonnes is required per annum.

The plant will produce the much-needed chemicals for the local and regional mining industry as well as the water treatment and manufacturing sectors. At present, such chemicals are mostly being imported at a premium.

To find out more, please visit our website on: http://calculus-industries.com/

Content contributed by Calculus Industries